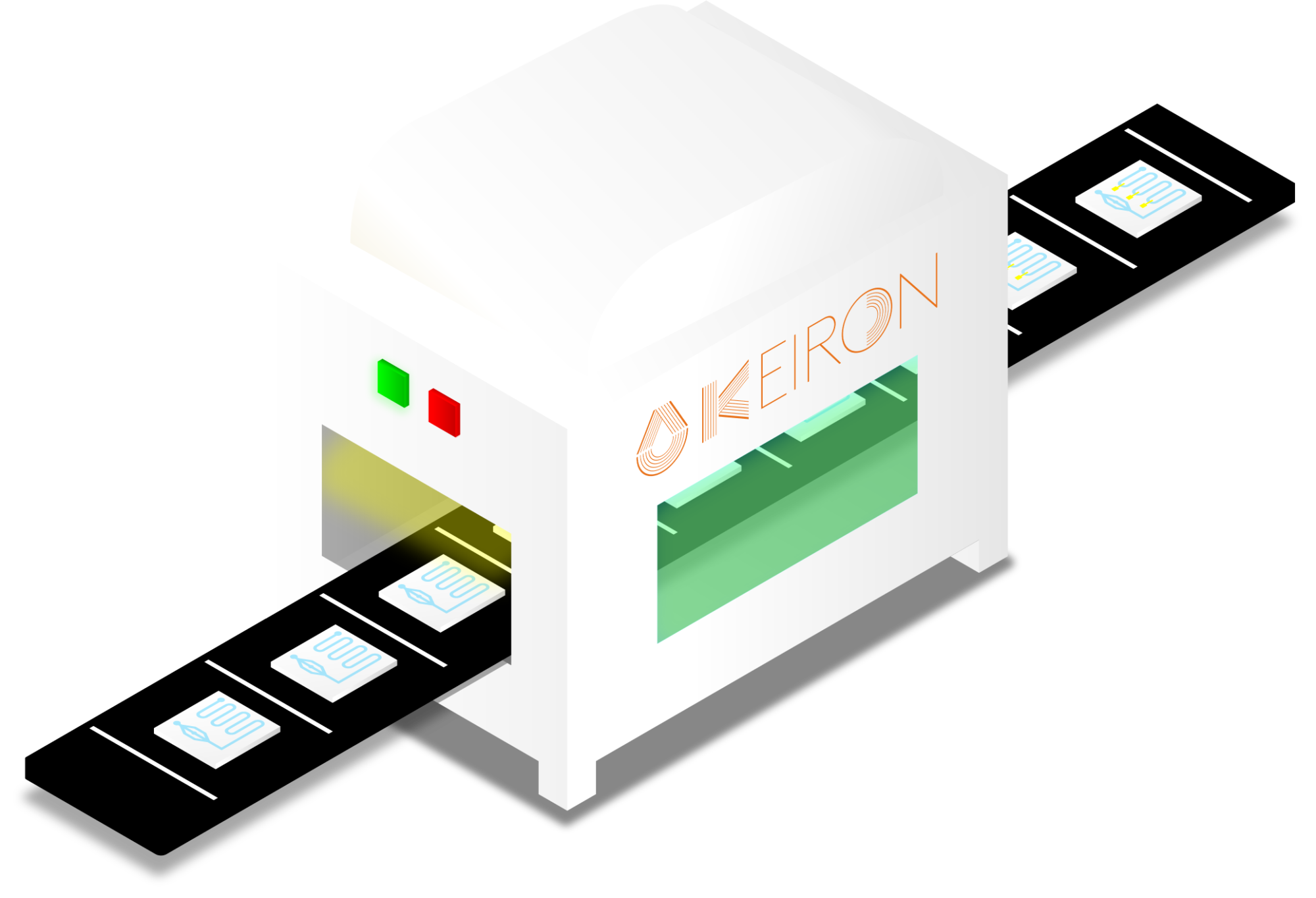

The technology developed by Keiron elevates the process of printing micro-electronics to the next level. The approach used by this TNO spinoff is suitable for the targeted delivery of both solid and liquid materials on any surface. Its main application is installing micro-electronics on chips. It has brought the mass production of flexible electronics one step closer.

Keiron’s technology makes it possible to add complex functionalities during the actual production process of the chips. The innovation opens myriad doors for this industry.

Rife with opportunities

Laser-based technology is widely applicable for the printing of electronic connections. Both the conductive materials and the insulation can be printed simultaneously during the production process. This is all done without making any actual contact. Contactless printing is one of the major benefits of this technology. The laser can create any pattern on a surface all at once and extremely quickly. This means the manufacturer is no longer dependent on mechanical movements that only work with liquid materials to begin with. The application of solid materials such as metals is also possible. All in all, this technology paves the way for the mass production of integrated electronics on a microscopic scale.

Lab at home

Keiron’s technology has another ground-breaking application. The addition of micro-electronics in chips marks one more step towards the ultimate goal of conducting laboratory research in people’s homes. Think of e.g. analyzing blood and other bodily substances or making diagnoses that would otherwise require a visit to a physician or specialist. Keiron makes it possible to print sensitive biological materials, such as cells. This makes the technique ideally suited for applications in the field of microfluidics.

Jimmy Sy-A Chin, CEO of Keiron

“I have only good things to say about the application process of the TTT. We were asked to submit a one-page document, rather than a convoluted and bureaucratic narrative. In the past, some subsidy applications took so much time that we had to give it up altogether or outsource the application process. As a startup, you are doing a million things at once and there is never enough time for any of it. However, the TTT application process allowed us to spend our precious time on other things.”

Keiron received a voucher from the TTT Smart Industry to develop its business case. Jimmy: “We used those assets primarily for our acquisition and the preparation for client interviews. We created a kind of menu to clearly explain what our technology does. This resulted in a host of positive and surprised reactions. Ours is a growth market, which makes it all the more important to get clients thinking about new designs and applications. This menu helped us do just that.”